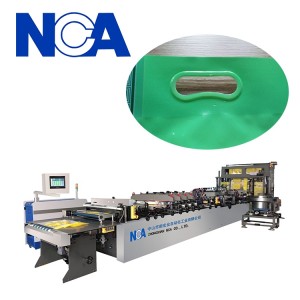

NCA1609A flexibilia Pouch et spout automatic signantes apparatus

Usuria

L.The apparatus adhibetur ad weld a plastic spout ad flexibilia pera.

2.It apta packaging bibit, gelata, SOY condimentum, flavorings et stibio (lac, faciem larva) etc ..

Commodum

I, mechanica signatio; ① parvum strepitu; ②better sigillum qualitas; ③saving compressionem aere; ④Extend usura vita

II, variis function: Center / anguli spout pera; Celeritate 140-150PCs / min

III, recta-type layout; ①lll operators, nisi in laboribus; ②it operit parva area; ③easy ad operari et adjust.

Opus processus

Spout lining up → spout feeding → pouch putting over → first hot sealing→pushing into main machine→ hot sealing 1→ hot sealing 2 → hot sealing 3 → cold sealing and shaping →branch hot sealing to strengthen → finished product putting into plastic grooves → wasted products removing.

Pelagus Technical Specification

|

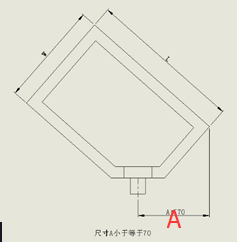

Pouch magnitudine (L ×) | Center Spout Pouch (100-190) × (70-120) mm (diversis massa mole necessitates ad adjust vel mutare per massa tristique adcommodare tabula.) |

| Anguli Spout Pouch (100-160) × (70-110) mm (Alia peraquagam magnitudinem necessitates ad mutare pera tank, comitante frame etc.) Max angle XLV gradu Magnitudine ≦ 70mm Nota: Quod apparatus est cum angulo functio, si opus ad facere corner peram, tantum addere ad mina cisternina et comitante frame extra. | |

| Spot type | Long aut brevi spout cum Bayonet, suppleverunt a elit. |

| Productio efficientiam | 120-140pcs / min Note: De productione efficientiam variat propter materiam et differentiam in manticae magnitudine. |

| Potentia | AC380V, 50Hz, 18kW, 3P |

| Compressum aeris | 0.5-0.7MPA, 450nl / min |

| Dimensionem (L × W × h) | (V) DCCC × MMMDCCL × 2270mm (including spot elevatio fabrica) |

| Refrigerandum aquae | 6L / min |

| Pondus | 3500kg |